Scopus Indexed

Scopus Indexed

Article Peer-Reviewed

Open

Peer Review

Peer Review

Best Practice for Right to Repair and Supply Chain Regulations: High-reparability Modular Smartphone Usage Model Mitigates Environmental Hotspots

Center for Environmental Systems Research, Kassel Institute for Sustainability, University of Kassel, 34117 Kassel, Germany

*

For correspondence.

Academic Editor:

Received: 7 October 2024 Accepted: 28 January 2025 Published: 20 February 2025

Abstract

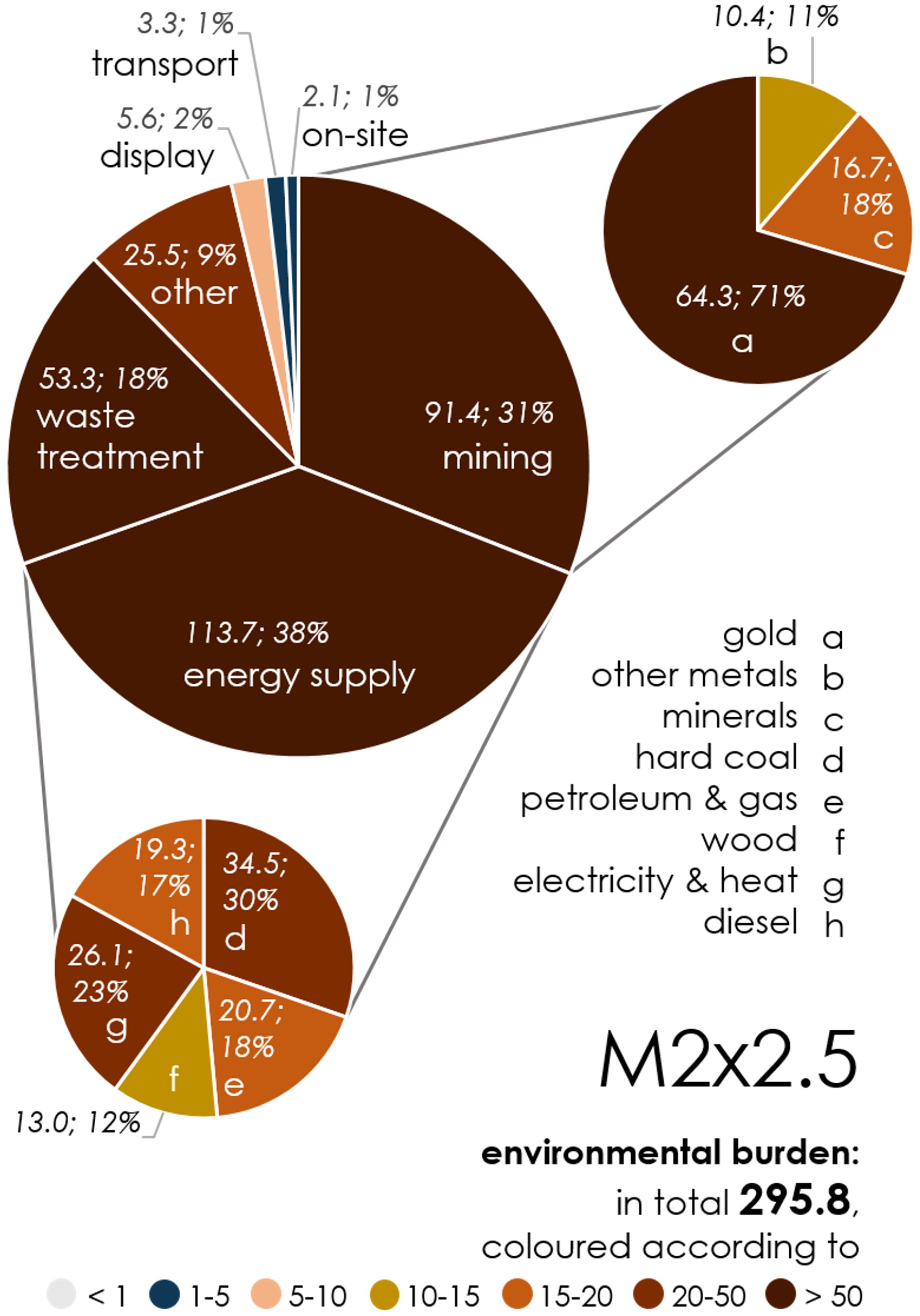

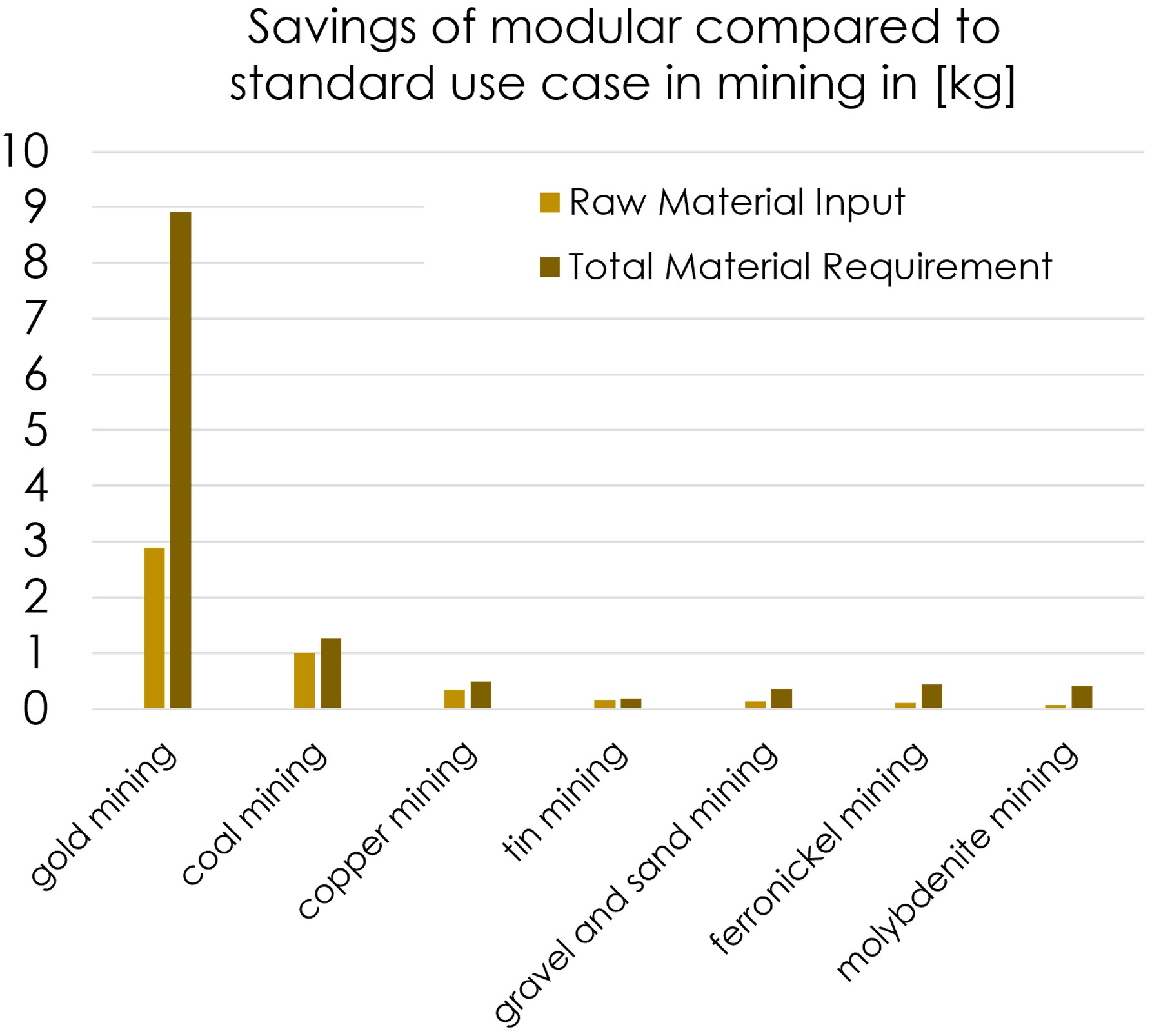

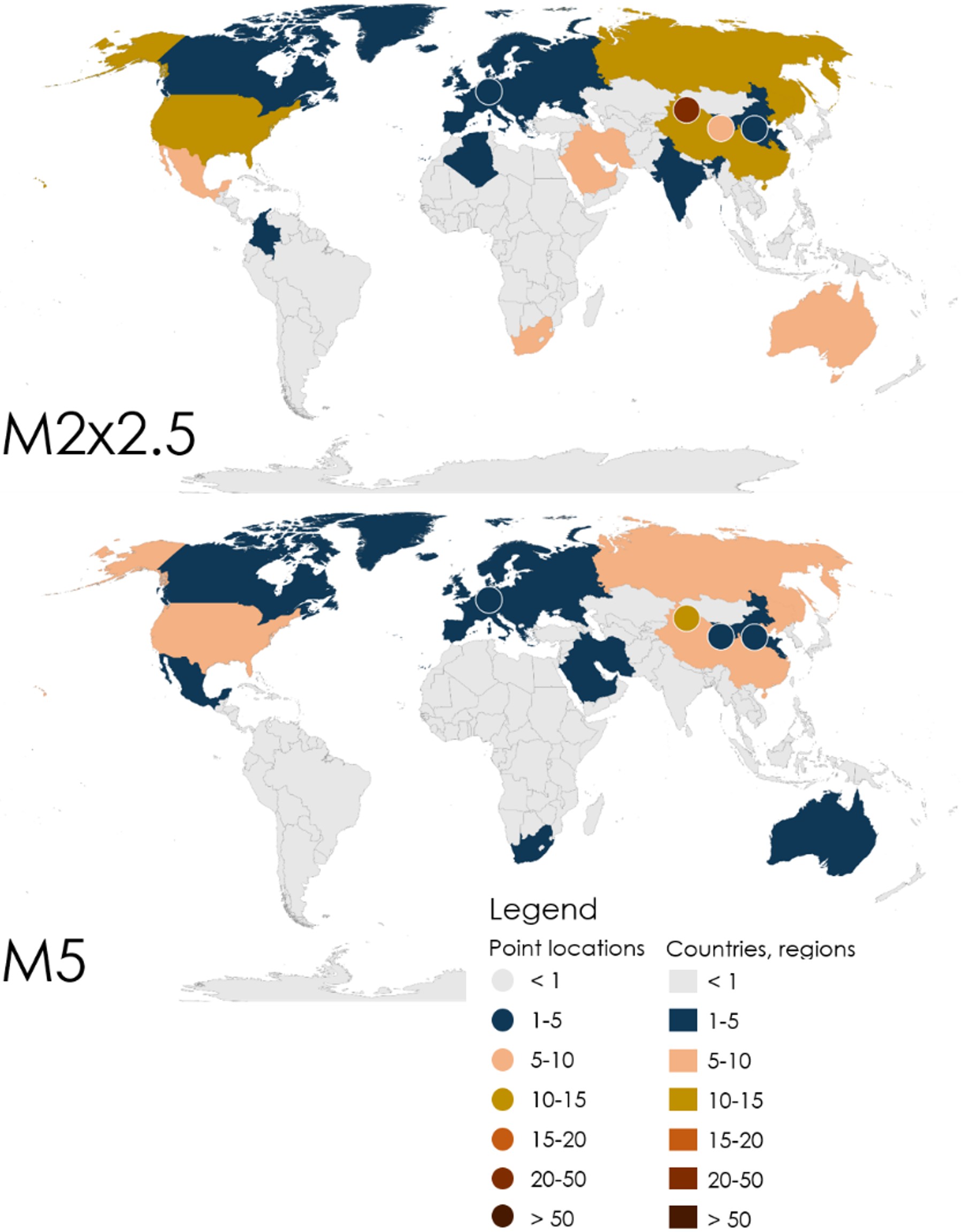

Two-thirds of the global population own mobile phones or smartphones. Yet their short service life—often limited to just a few years—leads to frequent replacements, excessive raw material consumption, and rising electronic waste. This study evaluates the environmental benefits of a highly modular and repairable smartphone, based on real-world usage. Compared to conventional smartphones with an average lifespan of 2.5 years, this device achieves a lifespan of five years, enabled by user engagement and a modular design that facilitates easy repairs. This finding is substantiated by customer surveys. Verified through manufacturer data, our life cycle assessment reveals a 40% reduction in climate emissions, energy use, material consumption, water usage, and land occupation. A high-resolution hotspot analysis reveals significant reductions in environmental impacts along the supply chain, particularly in mining and energy-intensive processes. The advanced usage model—aligns with the European Commission’s “Right to Repair” and supply chain legislations—provides a scalable best-practice example to enhance smartphone sustainability and alleviate global supply chain pressures.

Figures in this Article

Figure 1

Figure 1

Figure 2

Figure 2

Figure 3

Figure 3

Figure 4

Figure 4

Would you like to reuse the images? Contact the journal editorial office to obtain high-quality versions.

Keywords

Copyright © 2025

Schomberg et al. This article is distributed under the terms of the Creative Commons Attribution License (CC BY 4.0), which permits unrestricted use and distribution provided that the original work is properly cited.

Funding

This research work was performed as part of the project “Closing the loop: SHIFTPHONE is ready for circular economy”, loopPHONE (033RK087B), carried out with the support of the Federal Ministry of Education and Research (BMBF).

Cite this Article

Schomberg, A. C., Mostert, C., & Bringezu, S. (2025). Best Practice for Right to Repair and Supply Chain Regulations: High-reparability Modular Smartphone Usage Model Mitigates Environmental Hotspots. Highlights of Sustainability, 4(1), 38–55. https://doi.org/10.54175/hsustain4010003

References

1.

Bekaroo, G., & Seeam, A. (2016). Improving wireless charging energy efficiency of mobile phones: Analysis of key practices. In 2016 IEEE International Conference on Emerging Technologies and Innovative Business Practices for the Transformation of Societies (EmergiTech) (pp. 357–360). IEEE. https://doi.org/10.1109/EmergiTech.2016.7737366

2.

Bekaroo, G., Bokhoree, C., & Pattinson, C. (2016). Impacts of ICT on the natural ecosystem: A grassroot analysis for promoting socio-environmental sustainability. Renewable and Sustainable Energy Reviews, 57, 1580–1595. https://doi.org/10.1016/j.rser.2015.12.147

3.

Gurita, N., Fröhling, M., & Bongaerts, J. (2018). Assessing potentials for mobile/smartphone reuse/remanufacture and recycling in Germany for a closed loop of secondary precious and critical metals. Journal of Remanufacturing, 8, 1–22. https://doi.org/10.1007/s13243-018-0042-1

4.

OECD Environment Directorate. (2010). Materials Case Study 1: Critical Metals and Mobile Devices.

5.

UNEP International Resource Panel. (2013). Global Metal Flows Working Group Report 3: Environmental Risks and Challenges of Anthropogenis Metals Flows and Cycles.

6.

Park, S.-H., Shin, J.-A., Park, H.-H., Yi, G. Y., Chung, K.-J., Park, H.-D., et al. (2011). Exposure to volatile organic compounds and possibility of exposure to by-product volatile organic compounds in photolithography processes in semiconductor manufacturing factories. Safety and Health at Work, 2(3), 210–217. https://doi.org/10.5491/SHAW.2011.2.3.210

7.

Banza Lubaba Nkulu, C., Casas, L., Haufroid, V., De Putter, T., Saenen, N. D., Kayembe-Kitenge, T., et al. (2018). Sustainability of artisanal mining of cobalt in DR Congo. Nature Sustainability, 1, 495–504. https://doi.org/10.1038/s41893-018-0139-4

8.

Parajuly, K., Kuehr, R., Kumar Awasthi, A., Fitzpatrick, C., Lepawsky, J., Smith, E., et al. (2019). Future E-Waste Scenarios. The StEP Initiative, UNU-ViE SCYCLE, and UNEP IETC.

9.

Perkins, D. N., Brune Drisse, M.-N., Nxele, T., & Sly, P. D. (2014). E-waste: A global hazard. Annals of Global Health, 80(4), 286–295. https://doi.org/10.1016/j.aogh.2014.10.001

10.

Forti, V., Baldé, C. P., Kuehr, R., & Bel, G. The Global E-Waste Monitor 2020: Quantities, flows and the circular economy potential. United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR) – co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Rotterdam.

11.

Kyere, V. N., Greve, K., Atiemo, S. M., Amoako, D., Aboh, I. J. K., Cheabu, B. S. (2018). Contamination and health risk assessment of exposure to heavy metals in soils from informal e-waste recycling site in Ghana. Emerging Science Journal, 2(6), 428–436. https://doi.org/10.28991/esj-2018-01162

12.

Nasr, N., Russell, J., Bringezu, S., Hellweg, S., Hilton, B., Kreiss, C., et al. (2018). Re-defining Value – The Manufacturing Revolution. Remanufacturing, Refurbishment, Repair and Direct Reuse in the Circular Economy. A Report of the International Resource Panel. United Nations Environment Programme.

13.

Romare, M., Harris, S., Zhang, Y., Steen, B., & Hennlock, M. (2021). Investigating the Potential Circularity of a Phone Using Life Cycle Assessment. IVL Swedish Environmental Research Institute.

14.

European Commission. (2023). Proposal for a Directive of the European Parliament and of the Council on Common Rules Promoting the Repair of Goods and Amending Regulation.

15.

Ercan, M., Malmodin, J., Bergmark, P., Kimfalk, E., & Nilsson, E. (2016). Life Cycle Assessment of a Smartphone. Proceedings of ICT for Sustainability 2016, 124–133. https://doi.org/10.2991/ict4s-16.2016.15

16.

Cordella, M., Alfieri, F., & Sanfelix, J. (2021). Reducing the carbon footprint of ICT products through material efficiency strategies: A life cycle analysis of smartphones. Journal of Industrial Ecology, 25(2), 448–464. https://doi.org/10.1111/jiec.13119

17.

Ercan, E. M. (2013). Global Warming Potential of a Smartphone Using Life Cycle Assessment Methodology [Master’s Thesis]. Royal Institute of Technology.

18.

Wiche, P., Pequeño, F., & Granato, D. (2022). Life cycle analysis of a refurbished smartphone in Chile. E3S Web of Conferences, 349, 01011. https://doi.org/10.1051/e3sconf/202234901011

19.

Pamminger, R., Glaser, S., & Wimmer, W. (2021). Modelling of different circular end-of-use scenarios for smartphones. International Journal of Life Cycle Assessment, 26, 470–482. https://doi.org/10.1007/s11367-021-01869-2

20.

Zink, T., Maker, F., Geyer, R., Amirtharajah, R., & Akella, V. (2014). Comparative life cycle assessment of smartphone reuse: Repurposing vs. refurbishment. International Journal of Life Cycle Assessment, 19, 1099–1109. https://doi.org/10.1007/s11367-014-0720-7

21.

Proske, M. (2022). How to address obsolescence in LCA studies – Perspectives on product use-time for a smartphone case study. Journal of Cleaner Production, 376, 134283. https://doi.org/10.1016/j.jclepro.2022.134283

22.

Schischke, K., Proske, M., Nissen, N. F., & Schneider-Ramelow, M. (2019). Impact of modularity as a circular design strategy on materials use for smart mobile devices. MRS Energy and Sustainability, 6, E16. https://doi.org/10.1557/mre.2019.17

23.

Nissen, N. F., Schischke, K., Proske, M., Ballester, M., & Lang, K.-D. (2017). How modularity electronic functions can lead to longer product lifetimes. In C. A. Bakker & R. Mugge (Eds.), PLATE: Product Lifetimes and The Environment (Vol. 6, pp. 303–308). IOS Press. https://doi.org/ 10.3233/978-1-61499-820-4-303

24.

Tröger, N., Wieser, H., & Hübner, R. (2017). Smartphones Are Replaced More Frequently than T-Shirts. Patterns of consumer use and reasons for replacing durable goods. AK Europa.

25.

Cordella, M., Alfieri, F., Clemm, C., & Berwald, A. (2021). Durability of smartphones: A technical analysis of reliability and repairability aspects. Journal of Cleaner Production, 286, 125388. https://doi.org/10.1016/j.jclepro.2020.125388

26.

Abbondanza, M. N. M., & Souza, R. G. (2019). Estimating the generation of household e-waste in municipalities using primary data from surveys: A case study of Sao Jose dos Campos, Brazil. Waste Management, 85, 374–384. https://doi.org/10.1016/j.wasman.2018.12.040

27.

Deutsches Insitut für Normung e.V. (2016). DIN EN ISO 14040:2006: Umweltmanagement – Ökobilanz – Grundsätze Und Rahmenbedingungen (in Germany).

28.

DIN-Normausschuss Bauwesen. (2023). Nachhaltigkeit von Bauwerken - Umweltproduktdeklarationen - Grundregeln for Die Produktkategorie Bauprodukte; Deutsche Fassung EN 15804:2012+A2:2019 + AC:2021 (in Germany).

29.

Schomberg, A. C., Bringezu, S., Flörke, M., & Biederbick, H. Spatially explicit life cycle assessments reveal hotspots of environmental impacts from renewable electricity generation. Communications Earth & Environment, 3, 197. https://doi.org/10.1038/s43247-022-00521-7

30.

Egenolf, V., & Bringezu, S. (2019). Conceptualization of an indicator system for assessing the sustainability of the bioeconomy. Sustainability, 11(2), 443. https://doi.org/10.3390/su11020443

31.

Steinmann, Z. J. N., Schipper, A. M., Hauck, M., & Huijbregts, M. A. J. (2016). How Many Environmental Impact Indicators Are Needed in the Evaluation of Product Life Cycles? Environmental Science & Technology, 50(7), 3913–3919. https://doi.org/10.1021/acs.est.5b05179

32.

Deutsches Insitut für Normung e. V. (2016). DIN EN ISO 14046:2016-07: Umweltmanagement – Wasser-Fußabdruck – Grundsätze, Anforderungen Und Leitlinien (ISO 14046:2014) (in Germany).

33.

Forster, P., Storelvmo, T., Armour, K., Collins, W., Dufresne, J.-L., Frame, D., et al. (2021). The Earth’s Energy Budget, Climate Feedbacks, and Climate Sensitivity. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change (pp. 923–1054). Cambridge University Press. https://doi.org/10.1017/9781009157896.009

34.

Hischier, R., Weidema, B., Althaus, H.-J., Bauer, C., Doka, G., Dones, R., et al. (2010). Implementation of Life Cycle Impact Assessment Methods. Swiss Centre for Life Cycle Inventories.

35.

Pimentel, D., Hurd, L. E., Bellotti, A. C., Forster, M. J., Oka, I. N., Sholes, O. D., et al. (1973). Food production and the energy crisis. Science, 182(4111), 443–449. https://doi.org/10.1126/science.182.4111.443

36.

Boustead, I., & Hancock, G. F. (1979). Handbook of Industrial Energy Analysis. John Wiley & Sons.

37.

Sameer, H., Weber, V., Mostert, C., Bringezu, S., Fehling, E., & Wetzel, A. (2019). Environmental Assessment of Ultra-High-Performance Concrete Using Carbon, Material, and Water Footprint. Materials, 12(6), 851. https://doi.org/10.3390/ma12060851

38.

Mostert, C., & Bringezu, S. (2019). Measuring Product Material Footprint as New Life Cycle Impact Assessment Method: Indicators and Abiotic Characterization Factors. Resources, 8(2), 61. https://doi.org/10.3390/resources8020061

39.

Schomberg, A. C., Bringezu, S., & Flörke, M. (2021). Extended life cycle assessment reveals the spatially-explicit water scarcity footprint of a lithium-ion battery storage. Communications Earth & Environment, 2, 11. https://doi.org/10.1038/s43247-020-00080-9

40.

Kaiser, S., Prontnicki, K., & Bringezu, S. (2021). Environmental and economic assessment of global and German production locations for CO2-based methanol and naphtha. Green Chemistry, 23, 7659–7673. https://doi.org/10.1039/D1GC01546J

41.

Proske, M., Sánchez, D., Clemm, C., & Baur, S.-J. (2020). Life Cycle Assessment of the Fairphone 3. Fraunhofer IZM.

42.

Sánchez, D., Proske, M., & Baur, S.-J. (2022). Life Cycle Assessment of the Fairphone 4. Fraunhofer IZM.

43.

Andrae, A. S. G., & Vaija, M. S. (2014). To Which Degree Does Sector Specific Standardization Make Life Cycle Assessments Comparable?—The Case of Global Warming Potential of Smartphones. Challenges, 5(2), 409–429. https://doi.org/10.3390/challe5020409

44.

André, H., Ljunggren Söderman, M., & Nordelöf, A. (2019). Resource and environmental impacts of using second-hand laptop computers: A case study of commercial reuse. Waste Management, 88, 268–279. https://doi.org/10.1016/j.wasman.2019.03.050

45.

Jaeger-Erben, M., Wieser, H., Marwede, M., & Hofmann, F. (Eds). (2023). Durable Economies - Organizing the Material Foundations of Society. Transcript.

46.

Bringezu, S. (2022). Das Weltbudget. Das Weltbudget (in Germany). Springer Wiesbaden. https://doi.org/10.1007/978-3-658-37774-8

47.

Sameer, H., & Bringezu, S. (2021). Building information modelling application of material, water, and climate footprint analysis. Building Research & Information, 49, 593–612. https://doi.org/10.1080/09613218.2020.1864266

48.

Peters, E.-J. (2022). The Economic and Ecological Impact of Shifting to a Modular Smartphone Design [Bachelor’s Thesis]. University of Twente.

49.

Haucke, F. V. (2018). Smartphone-enabled social change: Evidence from the Fairphone case? Journal of Cleaner Production, 197, 1719–1730. https://doi.org/10.1016/j.jclepro.2017.07.014

50.

Revellio, F., Shi, L., Hansen, E. G., & Chertow, M. (1 September 2020). Sustainability paradoxes for product modularity: the case of smartphones. Electronics Goes Green 2020+, Berlin, Germany.

51.

Schischke, K., Proske, M., Pamminger, R., Glaser, S., Nissen, N. F., & Schneider-Ramelow, M. (2022). The “Environmental Activation Energy” of Modularity and Conditions for an Environmental Payback. In Z. S. Klos, J. Kalkowska, & J. Kasprzak (Eds.), Towards a Sustainable Future - Life Cycle Management (pp. 15–25). Springer, Cham. https://doi.org/10.1007/978-3-030-77127-0_2

52.

Mutchler, L. A., Shim, J. P., & Ormond, D. K. (2011). Exploratory Study on Users’ Behavior: Smartphone Usage. AMCIS 2011 Proceedings - All Submissions, 418.

53.

Njoku, A., Agbalenyo, M., Laude, J., Ajibola, T. F., Attah, M. A., & Sarko, S. B. (2024). Environmental Injustice and Electronic Waste in Ghana: Challenges and Recommendations. International Journal of Environmental Research and Public Health, 21(1), 25. https://doi.org/10.3390/ijerph21010025

54.

Baldé, C. P., Kuehr, R., Yamamoto, T., McDonald, R., D’Angelo, E., Althaf, S., et al. (2024). Global E-waste Monitor 2024. International Telecommunication Union (ITU) and United Nations Institute for Training and Research (UNITAR).

55.

Deng, Y., Wu, W., Zhang, X., Li, S., Song, X., & Wang, J. (2024). Overview of China’s Waste Electrical and Electronic Equipment Recycling in the Last Two Decades. Sustainability, 16(23), 10683. https://doi.org/10.3390/su162310683

56.

von Gries, N., & Bringezu, S. (2022). Using New Spare Parts for Repair of Waste Electrical and Electronic Equipment? The Material Footprint of Individual Components. Resources, 11(2), 24. https://doi.org/10.3390/resources11020024

57.

Ljunggren Söderman, M., & André, H. (2019). Effects of circular measures on scarce metals in complex products – Case studies of electrical and electronic equipment. Resources, Conservation and Recycling, 151, 104464. https://doi.org/10.1016/j.resconrec.2019.104464

58.

Mestanza-Ramón, C., Cuenca-Cumbicus, J., D’Orio, G., Flores-Toala, J., Segovia-Cáceres, S., Bonilla-Bonilla, A., et al. (2022). Gold Mining in the Amazon Region of Ecuador: History and a Review of Its Socio-Environmental Impacts. Land, 11(2), 221. https://doi.org/10.3390/land11020221

Metrics

Loading...

Journal Menu

Journal Contact

Highlights of Sustainability

Editorial Office

Highlights of Science

Avenida Madrid, 189-195, 3-3

08014 Barcelona, Spain

08014 Barcelona, Spain

Cathy Wang

Managing Editor